Diecasting is now an integral component of Malaysia’s manufacturing and supports various industries which depend on the use of precision-engineered components. It is a process for forming metals it involves forcing the melting metal in a mold for parts that have intricate forms and precise finishes. It is used extensively for industries like electronic, automotive telecoms, consumer products, that require quality, long-lasting components. In the last few years the industry of diecasting in Malaysia has seen a significant growth, benefited advances in technology and a highly skilled workforce and its strategically located within Southeast Asia. Nowadays, Malaysia is known for its proficiency in diecasting and providing precision components both locally as well as to international markets.

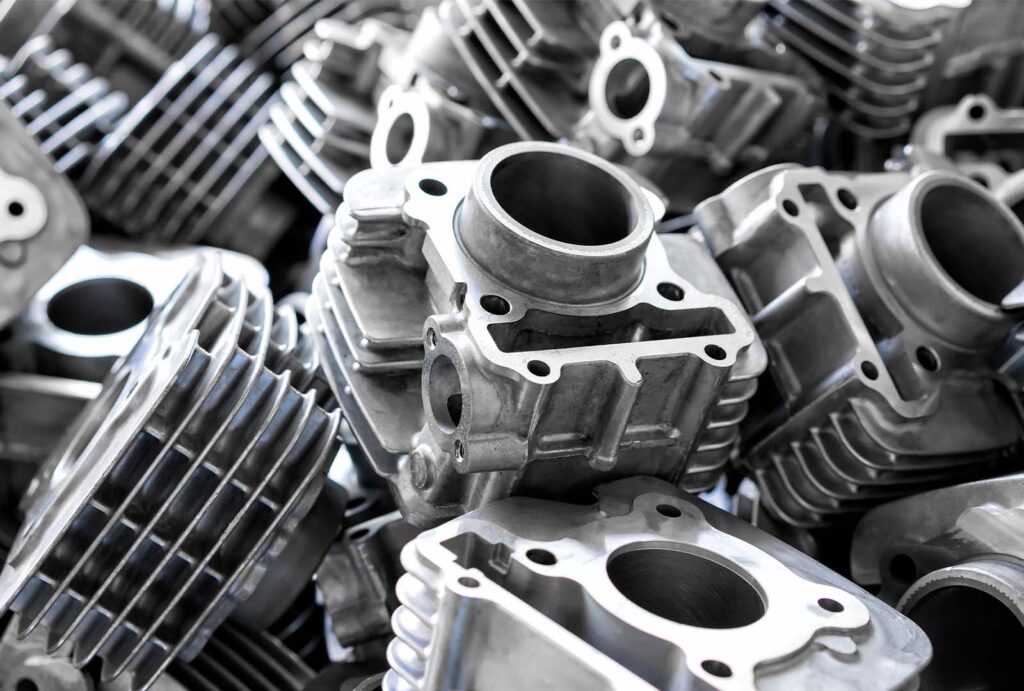

The auto sector in Malaysia is among the main drivers for diecasting. Automotive companies require parts that are light sturdy, robust, and affordable that makes diecasting the ideal method to produce engine components or transmission components as well as structural components. Malaysian diecasting businesses are able to create high-quality parts that are able to meet the rigorous specifications of the quality standards in the automotive sector. In collaboration with automobile manufacturers from both the world and local they have a significant role to play in the supply chain, and are integral in the creation of vehicles that are reliable, long-lasting and secure. The automotive industry is evolving in particular with the rise of electric cars, the need for light, high-performance and lightweight components will likely to increase and further boost the industry.

Apart from the automobile sector, Malaysia’s diecasting business is a major player in telecommunications and electronics sectors. With the increasing use of laptops, smartphones, and other telecommunications devices has led to the need for tiny complicated components that are able to be manufactured in a controlled manner with high precision. Diecasting allows you to make complex forms with tight tolerances. It is ideal for the production of connectors, casings as well as heat sinks that are used in electronic gadgets. Malaysian firms have developed their know-how in manufacturing tiny-scale parts, and have made sure that the components meet the high specifications required by electronic devices. Technology advances continue to advance with the development of diecasting, Malaysia is well-positioned for manufacturing of the next generation of products and the telecommunications infrastructure.

One of the main reasons for the popularity that diecasting has in Malaysia is the cost effectiveness. Diecasting is well-known for its capacity to create huge quantities of components rapidly and effectively, which makes it a perfect process in industries that require massive production. Malaysian companies that use diecasting have benefited from Malaysia’s low labor cost and the availability of raw materials and access to markets across Asia in order to deliver affordable solutions for their customers. The efficiency of diecasting, coupled with the advantageous manufacturing climate is what has made Malaysia an appealing destination for firms looking for reliable and cost-effective manufacturing partner. This advantage in cost has enabled Malaysian diecasting firms stay competitive on the international market and maintain the highest standards in quality as well as precision. For more information please visit here https://www.senadiecasting.com.my/

Sustainability is also an increasingly important aspect of Malaysia’s diecasting business. While industries across the globe strive to minimize their impact on the environment Diecasting firms in Malaysia have adopted practices to help to reduce waste and promote sustainability. Recycling scrap metal from diecasting is just one of the major benefits of this method of manufacturing which allows companies to reduce the amount of material that is wasted. Diecasting molds are also able to be used again for longer manufacturing runs. This is further decreasing consumption and saving resources. Malaysian diecasting businesses are investigating energy-efficient techniques and eco-friendly materials to decrease the carbon footprint of their operations. In implementing sustainable processes, the industry is moving in the right direction in the direction of more environmentally responsible production.

The future of the diecasting industry in Malaysia is looking promising. With the demand for high-end precision engineered parts increases across various sectors, Malaysian diecasting companies are set to grow their capacities and discover new market opportunities. Integrating advanced technology including robotics, automation and artificial intelligence the production process is likely to increase efficiency, decrease cost of production, and increase the quality of products. This will help Malaysian diecasting firms to remain at the forefront of a global market, while also meeting the changing demands of their customers. With a solid base set, Malaysia’s diecasting sector is poised for continued growth, contributing to Malaysia’s economic growth and consolidating its position as a major hub for top quality production, high-precision manufacturing.